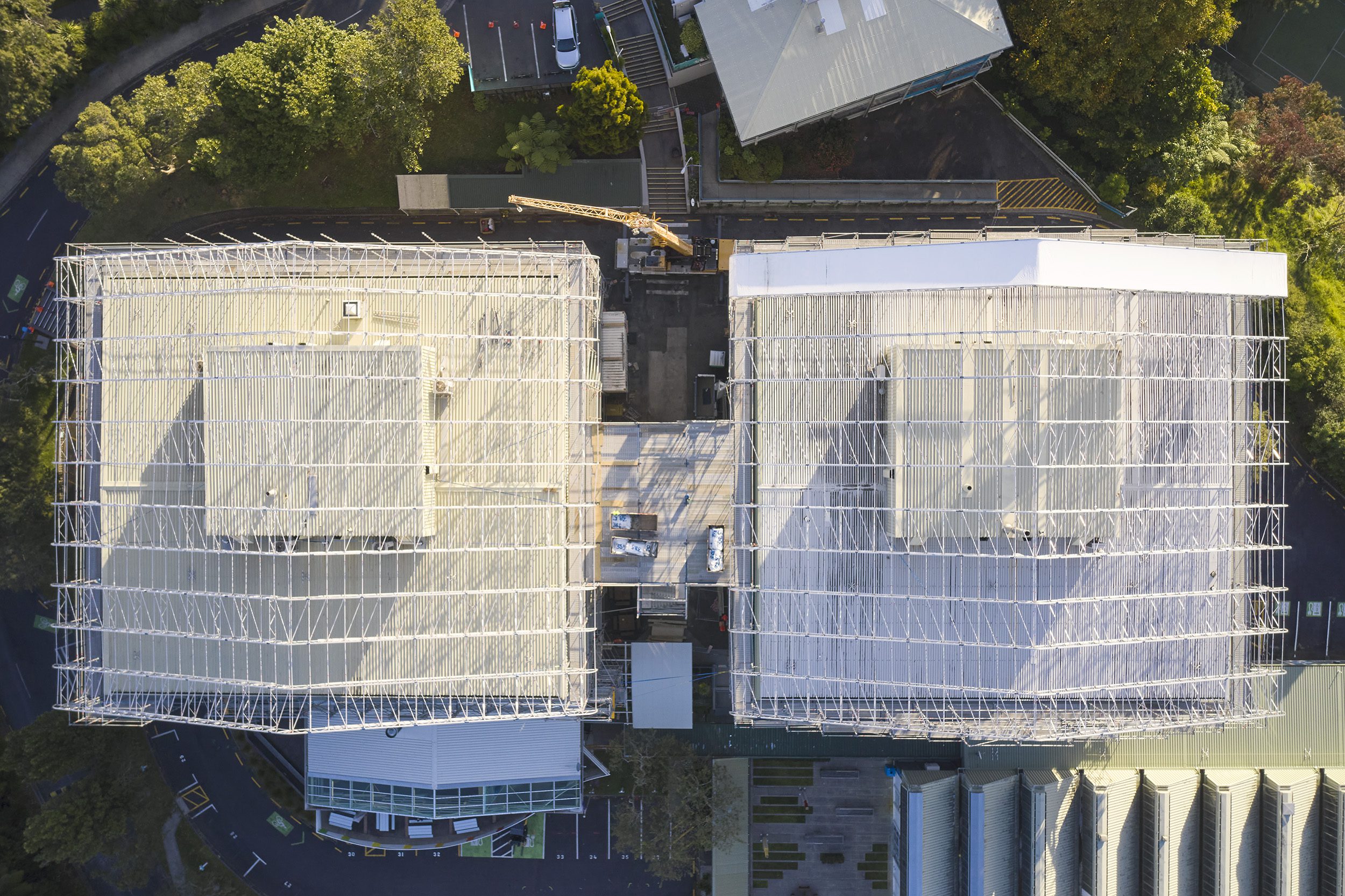

Livingstons have been a long-standing customer of CCL. As part of the project review, they requested the use of a Keder Roof over each block.

One key aspect of the job was to span a scaffold across the atrium of B Block, initially planned at approximately 22 meters but extended to 26.9 meters to accommodate pedestrian traffic entering the building from both sides of the atrium.

We collaborated with our long-standing partner, Layher, to design a façade scaffold capable of supporting the roofs. The scaffold’s apex was oriented east-west, considering the prevailing winds from the west. This setup facilitated the installation of the 6-ton AR bridging system over the atrium using a 140-ton crane.

The bridge was constructed on the ground with a preset camber, and all upper, lower, and diagonal bracing was installed before lifting.

Between the blocks, a birdcage scaffold was erected to the necessary working height, providing easy access to each block. A 1.09-meter wide stair access tower and a GEDA hoist were added to the birdcage scaffold for access and material handling.

With the design by Layher’s Edgar for the façade, Keder Roof, GEDA hoist, and AR bridge section, and engineering support from our partner Blue Barn, all elements were installed and engineered as per the design.

A crew of 10 completed the installation in approximately four weeks. The total weight of Layher equipment used was 104 tons.

It was a real pleasure being a part of this project. With its complexities around a large, suspended bridge portion as well two large Keder roofs, an adjoining loading bay and GEDA 1200 hoist there was a lot to consider in the pre planning phase. The client (Livingstone Building Ltd) were on board from the start as we promoted the environmental benefits of the solution we reached, reducing the need for over 2000 square metres of Shrink-wrap wastage along the way.

The engineering constraints and considerations were front and centre from the start. Layher was excited about the bridging system being the largest ever achieved in New Zealand and providing amazing support and assistance throughout the initial design phases through installation. Rod from Bluebarn was also instrumental in the development of our final design and execution of this unique build.

A massive thanks to our Team from Greg Lockley and Michael Lobb for their work on this, Blake Lucinsky and Peter Jagmis at the coal face, and Rangi Hiroti for his rigging expertise on this job.

Paul Cunningham

Managing Director

Cunningham Construction Ltd

WITT Te Pukenga New Plymouth

"We have developed a strong working relationship with Cunningham Construction over the past few years. When it came to constructing the scaffold structure and temporary roof on an active campus, we knew we needed a team that could meticulously plan and execute every detail while prioritising health and safety. Cunningham Construction’s expertise and experience allowed them to overcome any obstacles they encountered. Their knowledge of Layher and its systems is unparalleled. To minimise campus disruption, we requested accelerated installation in certain areas, and Cunningham Construction delivered flawlessly and ensured project success. We look forward to a bright future continuing to work alongside them.”

Jonathan Hicks

Project Manager

Livingstone Building

WITT Blocks A & B Project

"The scope given to us by CCL is to design a Keder Roof XL full encapsulation and 1.09m wide roof-edge access scaffold for blocks A& B of this WITT project. The challenge is to bridge across the lower atrium building at Block B, which is approximately 23.0m long.

Due to time restraints and the simplicity of the structure (“boxes”), CCL did not have to do a 3D scan of the building and we relied on the 2D PDF drawings and site measurements/confirmation. The CCL team has been very good in providing us accurate measurements on site to adjust our design and improve our accuracy.

This project has 2x 32.11m span Keder XL temporary roofing. We had to span the longer direction of the building to ensure that we reduced the loads on the temporary bridge over the atrium.

After many revisions, and confirmation from CCL’s Engineer (NZ CPEng), we came up with a bay layout that works for all parties and achieved the requirement to bridge across the atrium using our Layher Allround Bridging System (ARBS). We also managed to seamlessly connect the 2 buildings with a loading bay in between. The loading bay also has a stair at one end and is efficiently supplied with roofing materials using a GEDA 1200Z/ZP hoist at the other end. CCL owns a few GEDA hoists which are very useful for these projects.

The Layher ARBS is the strongest temporary bridge solution compatible with our Allround scaffold meaning CCL only needed a few additional components to implement this innovation. Though designed for bridge spans of up to 30m, the 26.94m span for the WITT project is the longest Layher ARBS ever built in NZ. To help with the build, Layher NZ conducted a familiarisation training for CCL’s crew to ensure that their first Layher ARBS will go smoothly. We also produced color-coded and step by step drawings to reduce possible errors on site and adjusted them as needed. 3D models have been created for all revisions which help in confirming designs faster.

CCL also used their local surveying company to ensure that scaffold legs are on the right locations and meant simultaneous work around the building could be started without worrying that roof/bridge supports will not align to each other."Edgardo Escaro Jr

BS(Civil Engineering), MEngNZ Technical Manager

Layher Limited